What you need to know when you are about to buy a made-to-measure suit? What is the difference between a bespoke suit and mtm-suit? In this post I try to give you a detailed look to the process of buying a made-to-measure suit. In addition I go through what points you should consider in that process.

Made-to-measure suit - what is that?

Made-to-measure suit, MTM, custom-made - a beloved child has many names. In general made-to-measure refers to a suit or a jacket made according customers dimensions, measurements and personal choices, but most of times in an outside factories.

Nowadays made-to-measure suits are often mixed with bespoke suits. However these two are totally different processes. To put is shortly, the distinction between these two is that bespoke suits are created without use of a pre-existing pattern. Made-to-measure suits instead are created by altering a standard-sized pattern to fit the customer.

Unfortunately today the boundary between made-to-measure and bespoke is often blurred. There are many manufacturers and brands who use the word “bespoke” in their marketing. And they do that even the service or product itself would not fit into the description of bespoke above.

Made-to-measure vs. Ready-to-wear

Every man must have at least one well-fitting suit. But does every man need to have a custom-made suit? “MTM or RTW” is a question that forums, blogs, and literature shows answers for and against. My own view is that not necessarily. The advantage of made-to-measure suits could be described as follow:

- freedom of choice

- fit

And these, in that particular order. It is clear that majority of men can not find a ready-to-wear suit that would fit them perfectly without any alterations. In fact, such people are very few. But they do exist. For them a made-to-measure suit does not provide such an added value compared to ready-to-wear suits in terms of fit. If you happen to fall into this category, and there is not that much use for suits in your rotation, it might be smart to invest the money elsewhere than to a made-to-measure suit.

The second group are people who can find a suit that fit alright, so that with little alterations done by a tailor, a perfect fit can be achieved. The number of these guys is already much bigger. Finally there is a third group, the guys whose body proportions differs so much from the dimensions and proportions used by rtw-clothing manufacturers that a well-fitting suit can not be found. Not even one that could be fixed by a tailor with a reasonable effort and cost. This group is the one to whom custom-made suits - in terms of fit - is the best, sometimes even the only option. In addition to bespoke of course.

Advantages of made-to-measure suits

In my opinion however the biggest advantage when it comes to made-to-measure suit is the fact that the suit can be made using the fabric of your personal choice. And you can choose exactly the details you want for your suit. On the other hand, it is also good to bear in mind that usually even for the guys belonging to those groups one and two mentioned above mtm-suit is an option that rarely fits worse than any of those pieces already hanging in their closets. Win-win situation for them, that is.

At the moment there are both - mtm- and rtw-pieces in my rotation. And I dare to say there is a place for both.

Buying a made-to-measure suit

The first thing to mention is the simple truth - never buy a made-to-measure suit online. I admit that ordering a shirt from online-operators can be successful. Nevertheless I have never yet come across a custom-suit or a sport coat ordered online that would be perfect in terms of fit and overall aesthetics. At this point I would suggest skipping the part of “learning the hard way”. Just save the money for that first “real custom suit”.

Shortly my advice is this: when you buy a custom suit, find a tailor who

- Is a professional

- With whom you can discuss about the commission and the related details and

- Who, if necessary is able to make modifications to the suit, or who, alternatively, have a skilled tailor - that can make these changes - to work with.

The most important thing in terms of the last point is to ensure that any modifications or alterations needed and done go through the seller. Only that way the changes are taken into account with the future orders in mind.

For what purpose are you buing the suit?

Another piece of advice is to think the purpose the suit is coming and what are you looking for. This can many times answer the question if it is reasonable first go through the possible rtw-options. Or is it better just start going through the fabric bunches in the first place. In case you are looking for a suit for longtime, daily use - for example a year-round business suit - my advice would be to invest in quality fabrics and so-called full canvas construction.

Suit construction - full canvas, half-canvas or fused

One of the most important things when it comes to the life of a jacket is the fabric you choose. But even more important is the construction. In general there are two type of constructions used to make a suit jacket or a sport coat. First there are jackets that are canvassed and secondly there are jackets that are fused.

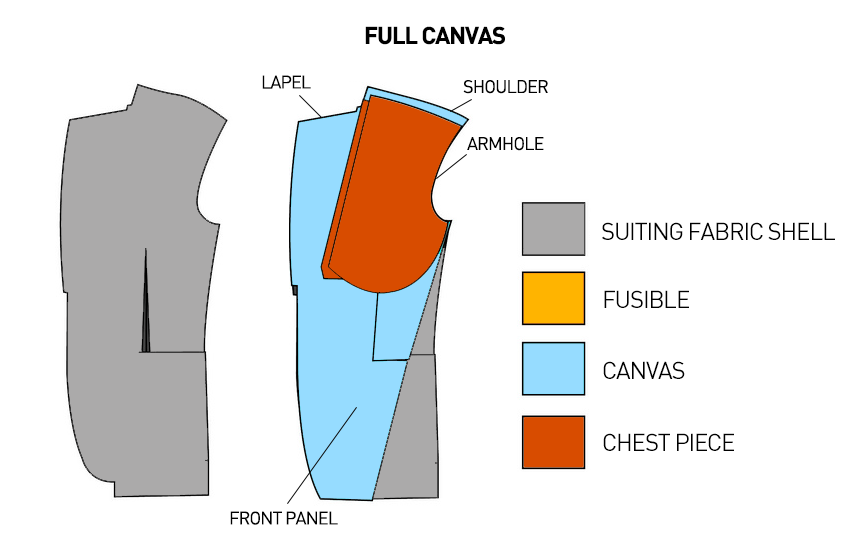

Full canvas

A jacket that has a canvas structure running all the way from the top of the shoulder to the hem features a “full canvas” construction. The idea of canvas - which is usually made of a blend of wool, cotton, and animal hair, mainly horse and camel hair - is to give natural roll and support to the front of the jacket. And help it to remain the right shape. A canvas made of wool and animal hair can be molded using humidity, pressure and heat so it is also easy to reshape the garment in case necessary. The floating canvas will also never delaminate. In general this construction will make your jackets last longer than the fused option.

Whether a jacket is fully-canvassed or not can be determined by the following method: Take hold of the lower front of the coat and peel the two layers of wool (the front and the facing) apart. If you can feel a third layer floating between the two, that is the canvas. If not, the jacket is fused. This test obviously does not apply to unconstructed jackets.

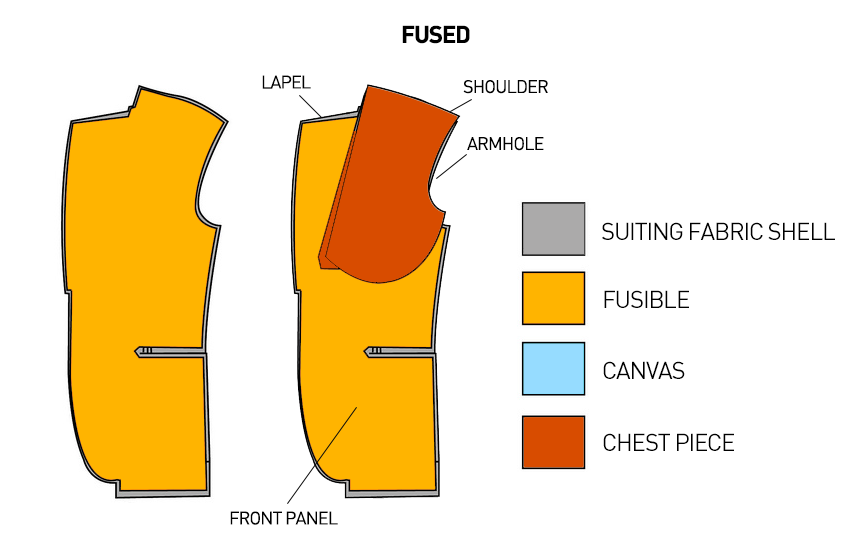

Fused jackets

Fusing and fusible interlining is a more recent innovation, made originally by the Germans. In this method, shortly, a fusible interlining replaces the main canvas portion of the understructure of the garment. What happens with fused structure is that it slightly stiffens the cloth. It does not provide the same type of support that animal hair does and it can be become somewhat flat and lifeless. The first thing however that you will notice is the fact that fused jackets will not “breathe” or evaporate moisture in the same way than canvassed jackets do. This will probably make you feel much more sweaty and sultry. On the other hand it is much more quicker, easier and also cheaper option.

Nowadays the techniques for fusing has come a long way. And there can be very nicely done fused jackets, especially in case the structure of the garment is very lightweight. So do not judge but bear in mind the differences. And finally make your call after you have estimated the pros and cons of different methods.

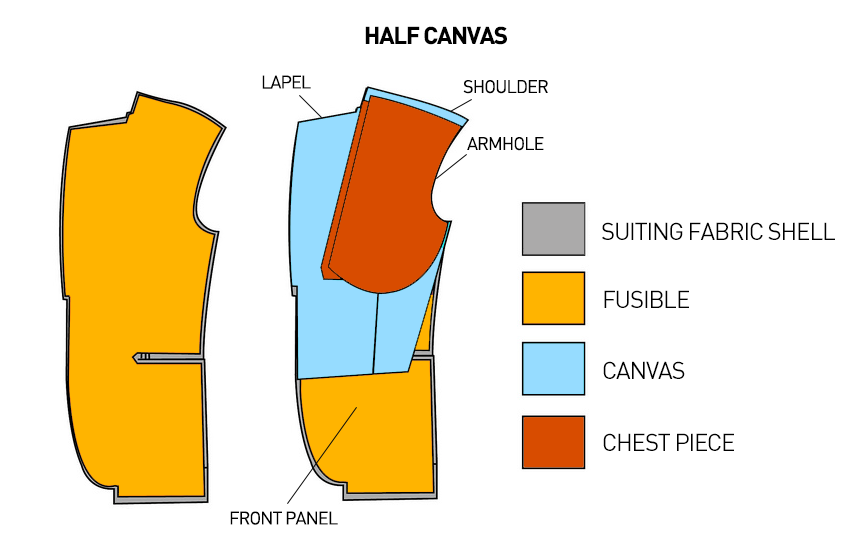

Half canvas

The so called half-canvas construction could be described as something in-between full-canvas and fused. Just as the name suggest. In half-canvas construction the canvas only covers the upper front (lapel area) of the jacket. The positive side of this option is that it’s less expensive than full-canvas. It is also less sensitive to humidity than fused construction and it usually gives the jacket a good lapel roll. As there is no canvas in the lower front you can't use the pinch test to determine whether a garment is half-canvas or not. But a well-aware tailor or a salesman can of course tell you what he is selling.

To get a full and comprehensive description of the differences between these ways I suggest to read the article “The difference between canvassed and fused suits explained” written by Jeffrey Diduch on Styleforum.

Ordering a made-to-measure suit - the process

Well, how does it happen then? How do you order a made-to-measure suit? At the moment I personally have seven mtm-suits in my closet; four of these are provided by Vaatturiliike Sauma and the three by Herrainpukimo in Turku. The process described below features mainly the process at Sauma. However the process itself works pretty much the same in all places so it does not make a real difference in this case.

Choosing fabric

The first step - choosing the fabric is, in my opinion the best part of the whole process. Choosing the fabric can be left even to be done as a final step, but I would recommend to start with it. This is mainly because the weight of the fabric, texture and the desired design will probably have more or less impact on other subsequent choices, such as the structure of the suit.

The right fabric and pattern may arise in seconds. But sometimes searching for the “the right one” can take weeks. Going through fabric bunches can be intoxicating and it’s easy to spend even hours just browsing. If you are not sure what kind of fabric would be suitable for your purpose, ask. A skilled tailor will know how to ask the right questions to find out the customer’s needs and then offer possible alternatives.

Fabric determines the price of the suit

In their private label line Sauma offers a range of basic (about 100 options) fabrics. Starting price - featuring full-canvas construction - is in between 1100 and 1400 euros. In addition, there are alternatives from several well-known fabric manufacturers. These include names such as Loro Piana, Holland & Sherry and Dormeuil. If even any of these is not suitable or the customer has already obtained a fabric of his own that he would like to use for his made-to-measure suit, this is in certain cases possible. Bear in mind that some of more special fabrics can easily double or even triple the price mentioned above.

Trial suit, construction and details

The second step is to choose the structure for the suit. Sauma provides an option to choose between Full Canvas- and Half Canvas. In case the customer wants an option as light as possible, there is also an unconstructured option available. At this point, it is mainly a question of what kind of look and feeling are you looking for.

Next choice, partly related to the suit structure is the lining of the jacket. Here again Sauma offers three options: Full lining, half-lining or the so-called unlined version. In the last one only the shoulders and sleeves are protected by lining. Once again you should think the purpose the suit is coming for. Are you looking for a year-round suit or a suit to use only during a specific season. A suit for business or a suit for leisure and casual occasions.

After decisions regarding fabric and structure has been done, it is time to put on a “fitting-suit” and start taking measurements. Unlike bespoke suits, made-to-measure suit is not done solely relying on tape and measurements. The necessary amendments are marked and transferred by a tailor to the system used for orders and later on transmitted to the factory. Finally the suit will be produced according the information provided.

Details

Next in line is choosing the details. And there are plenty of details to choose, believe me. Therefore, especially when you order the first made-to-measure suit, consider carefully what are the details that really count. And if you are not sure about something, it is worth to ask. Freedom of choice can be overwhelming so try to keep your choices simple. Keep in mind what purpose you are ordering the suit for.

Lapels and pocket of the jacket

In terms of the overall look the most relevant details to choose are the model of collar and pockets for the jacket. Notch lapels are a little bit more restrained and in my opinion more versatile choice. Peak lapels instead can be a good option if you look for a sharp-looking business attire. And of course for a double-breasted suit there is no other option than peak lapels. When it comes to pockets, once again the use of the jacket is determinative. Patch pockets are an appropriate option for more lightweight and casual suits and jackets. For business or formal use flap or jet pockets are a traditional choice.

Buttoning and shoulder structure

Other factors that affect to the formality of a suit are buttoning of the jacket and shoulder structure. In terms of the latter Sauma offers even five different options. There is for example padded shoulder - with more or a little less padding - for those looking for something more traditional. Then there is a soft shoulder option for those who want something a bit more lighter. And finally for those Italian peacock-menswear enthusiastics there is an option featuring a completely unstructured, Neapolitan style shoulder with pleats.

Remember to pay attention to the coherence and compatibility of your choices. All options do not work together.

As already mentioned, there are quite many details to choose. In fact you might even get a bit frustrated in case you haven’t given them any thoughts beforehand. But remember that there is no rush. A skilled tailor can and will always help you with your choices. And in case you are about to order a “basic suit”, you can also go with certain “default choices”.

Pay attention to the small details

Finally I will list a few of things I've had an opportunity to influence while making my orders in Sauma. Some of these are included to the price of the suit regardless of what kind of choice you make. Some others - such as the amount of handwork - however, may have an impact on the fact how much money you eventually will have to put on the table.

- Buttoning

- Finishing of the sleeves - amount of buttons and working button holes

- Lining cloth of the jacket

- Clefts

- Model and details of trousers - pockets, pleats, finishing

- Waist of trousers - belt loops / side adjusters, buttons for braces

- Initials - possible to have either on the lining of the jacket or under the collar

- Amount of handwork

Fitting of the suit

Details chosen and that’s it? Not quite. Delivery of a made-to-measure suit normally takes about four to six weeks. When the suit arrives, it’s time for a fitting. And amendments, in case needed. It is good to remember that mtm-suits, especially the first one you order from a new supplier will probably need some kind of altering.

According to Olli and Tuomo of Sauma about 60% of suits coming from the factory need some alterations before the suit can be handed over to the customer. . In most cases it is little amendments on sleeve or trouser length. Here it is good to go back to the advice I mentioned above - purchase your made-to-measure garments from a shop or a tailor that is able to make the necessary changes. And who will then register them up in order to have the amendments needed for upcoming orders. It is also good to keep in mind that the customer has already paid these alterations in the price of the suit. So there will be no added cost in case fixing is needed. Sometimes, it may happen that another round of alterations is needed, but after all it is the final result that counts.

Sum up - my made-to-measure suit in a nutshell

Finally I will just list the details I haven chose for most of my made-to-measure suits. These are basically my go-to choices.

- Unstructured jacket, unlined

- 3-roll-2 buttoning, notch lapels, 2 patch pockets for more casual jacket and jetted pocket for more business formal jackets

- Unconstructured shoulders with pleats

- Working buttons (4) on the sleeves

- No initilas anywhere

- A bit higher rise on the trousers, double pleats and no belt loops but side-adjusters instead

- 5cm cuffs on the trousers

You can also find this post in Finnish from @tyylit.fi

Original post 2/2015 - updated 3/2018.

Leave a comment